A History of Quality

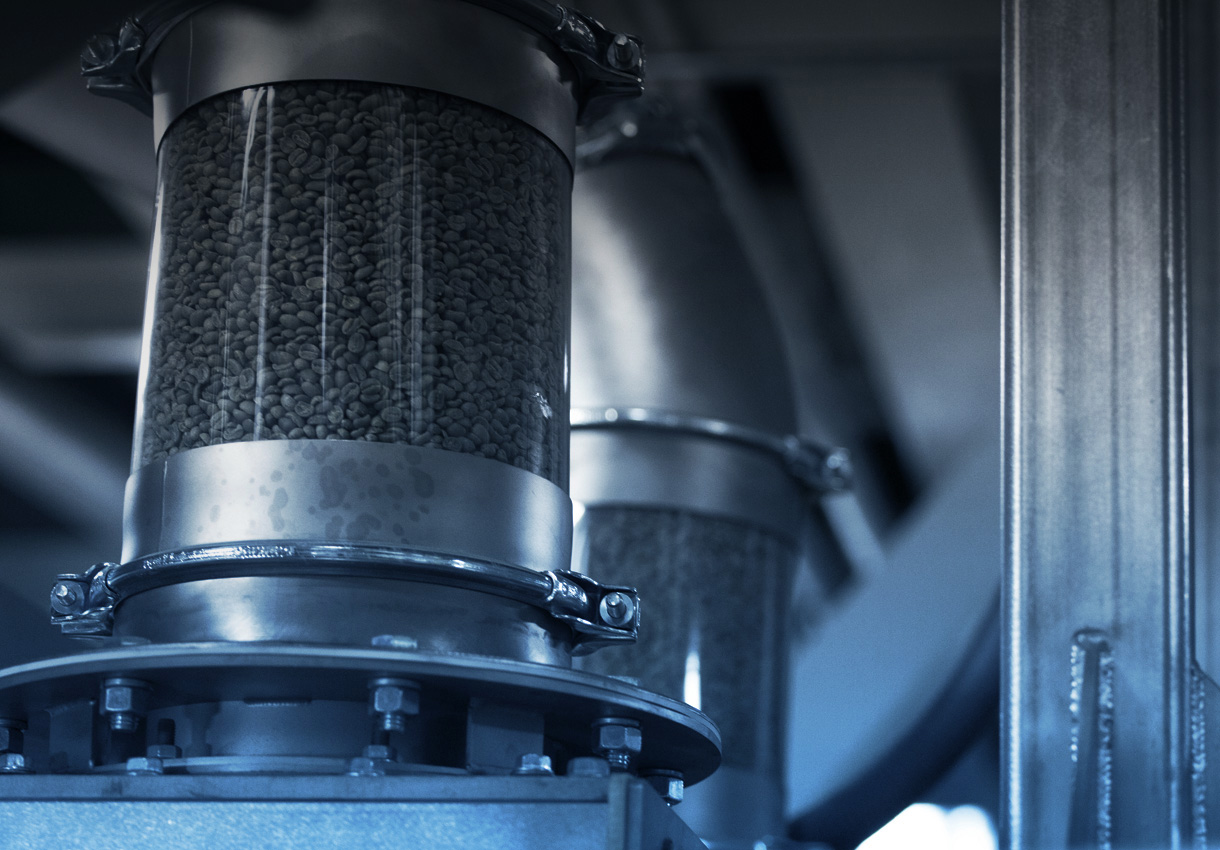

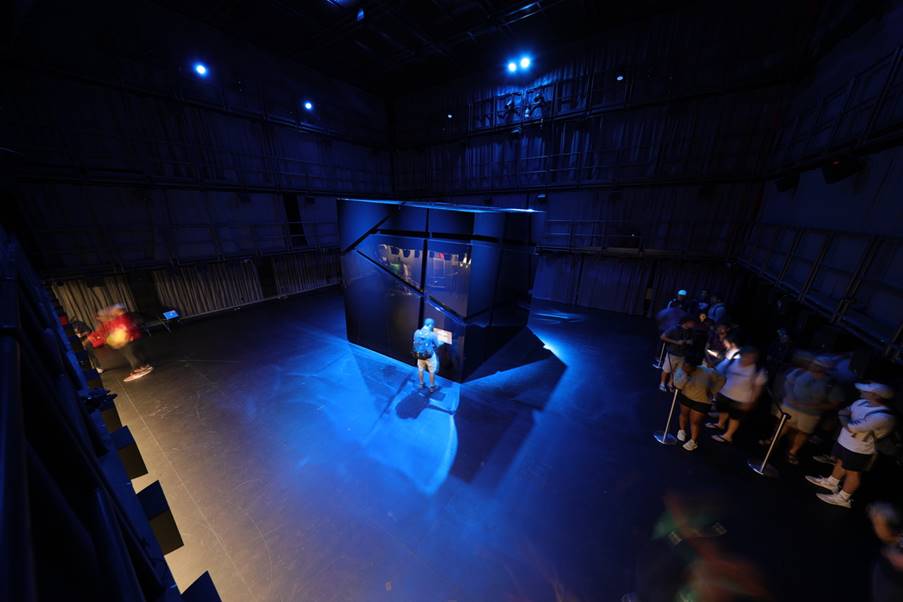

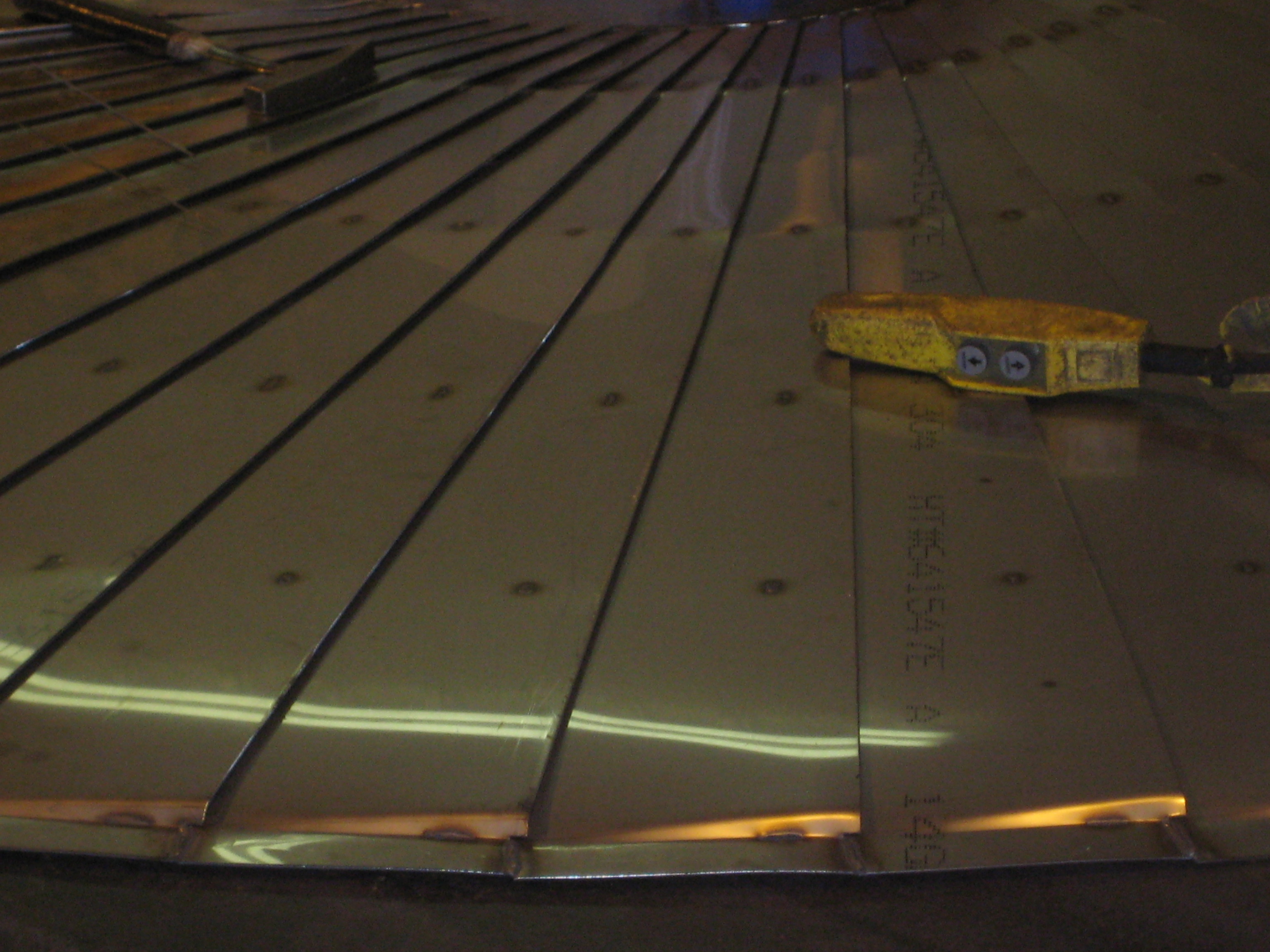

H&S Industrial is a custom solution for metal fabrication and quality mechanical contracting organization. With over 70 years of experience, we have the depth to serve as your single source for custom industrial design, fabrication and installation.